Search This Supplers Products:wall mirrorround wall mirrorbathroom mirrordecorative mirrormirrors for living roomvanity mirror

low-e glass

- group name

- Float glass

- Min Order

- 1 piece

- brand name

- oruii

- model

- low-e glass

- update time

- Tue, 23 Aug 2011 14:32:37 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Features of low-e glass.

Low emissivity coating glass are manufactured through coating several layer of metal oxide films o...

Low emissivity coating glass are manufactured through coating several layer of metal oxide films o...

Detailed

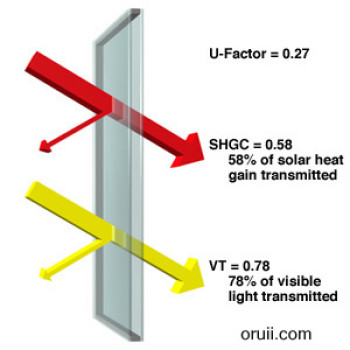

Features of low-e glass. Low emissivity coating glass are manufactured through coating several layer of metal oxide films on high quality transparent float glasses or tint glasses by the means of vacuum magnetism control and cathodic sputtering. Through different kinds of combination of metal oxide films, low emissivity coating glass is of good selection towards spectrum. It is able to received of great deal of near infrared and visible light to assure the brightness indoors. It can also prevent medium infrared an far infrared produced by heat source radiation. Thus, in hot summer, it is able to prevent the slolar radiation heat from entering the buildings to assure cool indoors; and in cold winter, it is able to make the radiation heat of air-conditioners and warming apparatus reflected indoors. Dimensions of low-e glass. Thickness: 1.8mm-22mm. Maximum dimensions: 96"x144" (2,440mmx3,660mm). Regular size: 1220x1830mm,1220x2440mm,2250x3210mm,2134x3050mm,2134x3300mm, etc. Size tolerance: +/- 0.2mm. Advantage of low-e glass. Compared with traditional glass, low emissivity coated glass have the following advantages. 1. Through different combination of various films, they have more prominent thermal insulation. performances and are able to realized warm in winter and cool in summer. 2. Suitable permeation rate of visible light is able to keep the indoors bright and comfortable, not dizzy in summer and limpid in winter. 3. Very low rate of glister is able to reduce light pollution. 4. Low-e glass are able to be bent and toughened. Due to their peculiar coating technology, the low-e glass sheet can be transported to the glass production base of our company for deep processing of flat toughening, bent toughening, hollowing and doubling to ensure rapid supply and services.